Table Of Content

Therefore molder always recommends uniform wall thickness for defect-free injection molded parts. Uniform wall thickness in injection molded parts ensures molten plastic is not passing through varying restrictions in the injection mold. The Following factors affect the quality and consistency of injection molded plastic parts. Aside from the main areas of a part, uniform wall thickness is an important design element for edges and corners. Adding generous radii to rounded corners will improve the design of a plastic part by reducing stress concentration and increasing the material's ability to flow.

Plastic Material Finishes

Also, it allows its incorporation into any production process or final product. For that reason, it is undeniable that the market for plastic products has a prominent place in the set of the economy. In this stage, all the decisions are taken from the economic, technical, and work process point of view (final design, expected manufacturing volume, estimated manufacturing cost, and production speed) to obtain the final product. At this point, it must be considered that there are companies that only design, but do not manufacture and vice versa.

Services

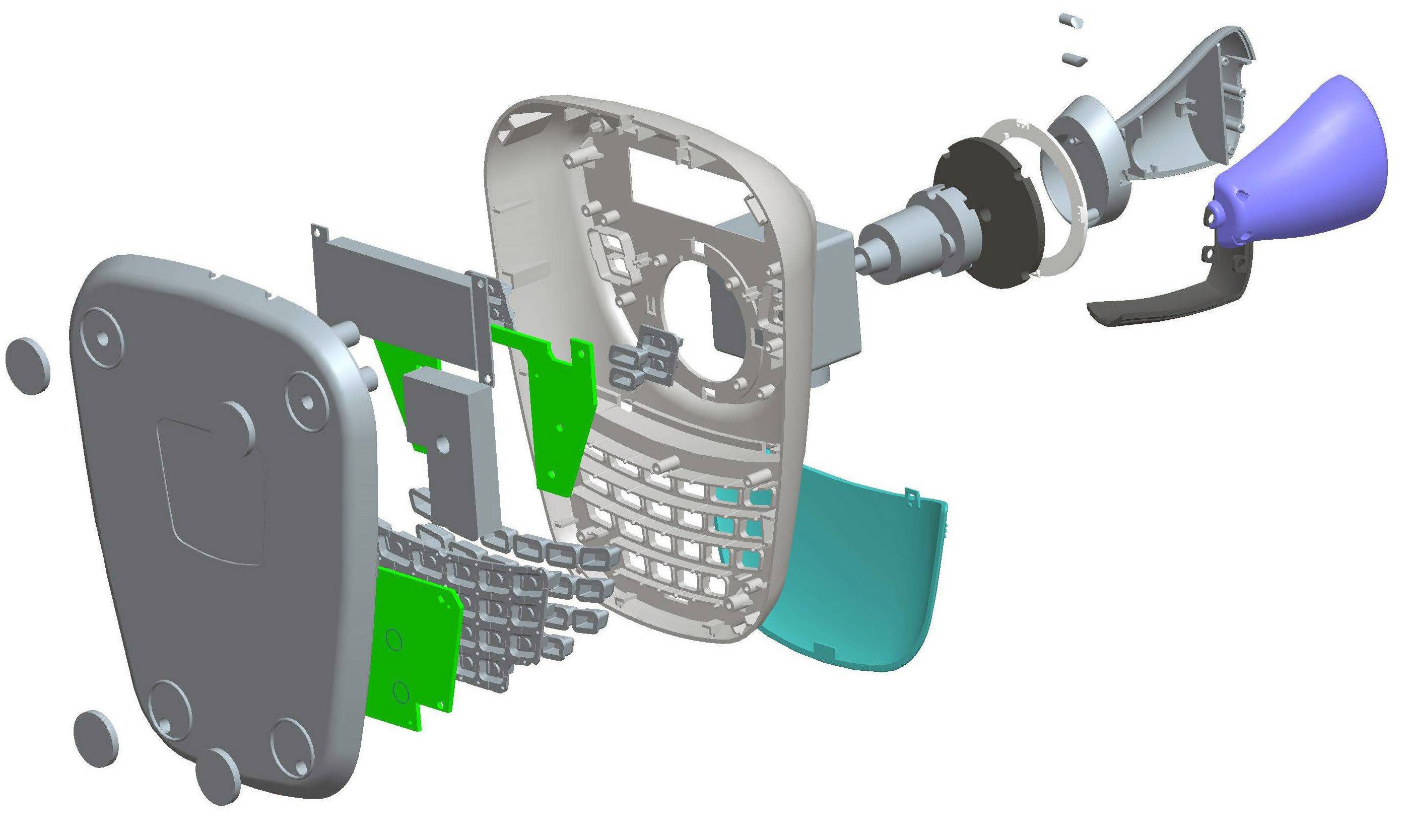

But it is not possible to follow all design guidelines because of product design constraints. Criador Labs has vast experience in plastic product design and manufacturing. Depending on the above data observed and the type of manufacturing selected, the CAD modeling is moved forward. Depending on the manufacturing method, many variables change and need to be kept in mind. For eg, for injection molding, it is advised to keep a Uniform Wall thickness within a range of 1.5mm - 3 mm. Its versatility can meet almost any design requirement, and its lightweight, durability, and versatility in color, touch, and shape give it significant marketing advantages.

Why study plastics engineering at UMass Lowell?

One of the most frequently utilized techniques for consolidating parts within a highly functional plastic part is incorporating snapfits. Molded-in snap locks enable designers to assemble parts without additional hardware. Although snap fits must be correctly designed for reliable performance, they are highly beneficial to the end-user and the manufacturer. The injection molding technique offers a fast and competitive way to produce a wide range of pieces. Through Debris, designers Shoma Furui and Kem Kobayashi aim to communicate the issue of environmental disruption subtly, using party accessories made from marine plastic collected from Makuhari Beach as material. The visually striking appearance resembles a cross-section of buried plastic waste, featuring pop patterns and textures created by the resin.

ThicknessIf a plastic part is too thick or has an uneven wall thickness, excess shrink, sink, internal bubbles and voids, and poor cosmetics are possible. This is a result of the plastic cooling from a molten state to a solid, room temperature state. To complete the process of the previous technique, the material is placed in a heated barrel, mixed and forced into a mold cavity, where it cures and hardens to the configuration of the cavity. The molds are usually made of steel or aluminum and are precision machined to form the characteristics of the piece. It involves the cost of the packaging material plus the operator to perform such an operation.

Dezeen In Depth explores the prospect of a plastic-free future

Eagle Vizion's Machine Vision System Inspects Shredded Plastic Particles - Vision Systems Design

Eagle Vizion's Machine Vision System Inspects Shredded Plastic Particles.

Posted: Wed, 15 Nov 2023 08:00:00 GMT [source]

Corners can lead to stresses, limit material flow, and often reduce part strength. Download the 7 Deadly Sins of Product Development and Design With BONUS blog notes, helpful business tips, industry news and timely trends. News from Dezeen Events Guide, a listings guide covering the leading design-related events taking place around the world. Although initially synonymous with stockings, the term nylon has since expanded to include a whole family of plastics composed of polyamides. These can be found in toothbrush bristles, films for food packaging and moulded components in cars and electronics. Extruded ABS pipes are more resilient than their PVC counterparts, making them suitable for constructing sewer systems and being repurposed into a corrugated seating collection by designer Phan Thao Dang (above).

When Mattel’s lead designer Roger Sweet was looking for a good toy idea, he just thought about giving the Marketing department something to sell. But in late 1980, he developed He-Man/Masters of the Universe toyline with such success, it resulted in its own cartoon series. This great versatility has made it possible for it to be an industry with extraordinary growth. This industry has managed to form part of the value chain of many and various products and to become a final consumer good.

To manufacture a new plastic product design, your supplier must have knowledge of industrial design, materials, industrialization, and product management, once its life cycle is over. Elements such as walls, ribs and holes require detailed scrutiny, for which general design guidelines and checklists provide basic principles. My experience involves designing machine components on the basis of stringent norms and international standards.

Thermoforming in Plastic-Vacuum Forming-Pressure Formed Plastics

For over 35 years, we’ve consistently delivered high-quality products on time and on budget to optimize our client’s marketing, manufacturing and functional needs. According to the British Plastic Federation, plastics versatility can meet almost any requirement from designers and customers. Also, their lightweight, durability, and versatility in color, touch, and shape give tremendous marketing advantages. It also worth to mention that plastic is an accessible material to work and mold. It has a low production cost, a low density, is waterproof, an excellent electrical insulator, good thermal insulation, and resistance to corrosion and many chemical factors.

The phrase “Design For Manufacturing (DFM)” describes the affect a product’s design has on its ability to be mass produced. If a product is too thick, has undercuts or insufficient draft, or poorly designed features, it will increase cost, slow production, and create other delays in getting your product to market. Conventional polymers can be replaced with biopolymers, recycled material.

This article covers various plastic part design guidelines for injection molding that you can implement in your part design to ensure good quality parts. Proper wall thickness is one of the most fundamental requirements in designing a part for plastic injection molding. Plastic shrinks as it cools which can lead to defects such as sink marks, voids, stresses, and warping. Plastic resin solidifies in the mold nearer to the outside of the part (closest to the mold surface). Thick sections of a part tend to pull inward, creating stresses, sink marks, or voids. Since thinner sections cool quicker, stress can build in the part between thinner and thicker sections, resulting in part warpage.

Our larger format machines routinely meet requests for hundreds of thousands and even millions of blisters or clamshells. Running fast equipment on two shifts with inline cutting, we typically are able to meet and surpass our customer's finished part usage requirements. Molder requires a minimum (1.5° + Part nominal draft angle ) per 0.025 mm texture depth for easy removal of parts.

It is generally called ‘tool’ and is designed by a tool designer and fabricated by an internal or external tooling supplier. The tooling concepts must be addressed at an early stage in the design process, as the tooling costs are highly dependent on the design features and the specifications for appearance. A tool consists of two mold halves, which form a cavity that defines the shape of a final part. Your plastic part design should always ensure injection molded plastic part quality. We can achieve a wide injection molding window if the plastic part design is as per design guidelines.

Industrial designers will always ask for zero drafts, But mold designers need max possible draft angle. Recommended inside corner radius in plastic pat design is more than 0.5 times the nominal wall thickness. Whereas recommended outside radius is inside radius plus nominal wall thickness. In design, it’s not always feasible to provide uniform wall thickness in all sections. Therefore following points are recommended to reduce the impact of non-uniform wall thickness. Plastic part manufacturers always recommend following the maximum possible design guidelines to manufacture defects-free plastic parts.

As we approach seven decades of service in the plastics industry, there is very little we have not seen. The newsletter also features an interview with interior designer Wearstler and a piece by interiors columnist Michelle Ogundehin on the increasing difficulty of navigating design trends in the social-media era. By hiring a freelance plastics engineer via Cad Crowd, you'll acquire your next indispensable team member and a highly motivated professional.

No comments:

Post a Comment